Printed Circuit Boards (PCBs) have undergone significant advancements and improvements since their inception in the mid-20th century. These innovations have been driven by the ever-evolving demands of the electronics industry, the miniaturization of components, and the need for greater efficiency and reliability in electronic devices. Over the years, several key improvements have transformed PCB design, making it more efficient, reliable, and adaptable to a wide range of applications.

Miniaturization and Component Density

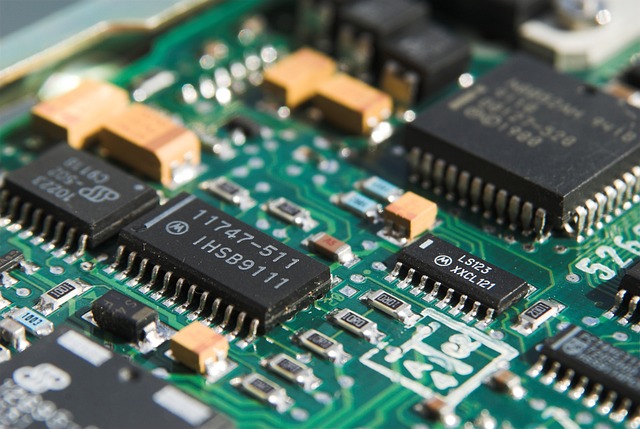

One of the most noticeable improvements in PCB design is the relentless drive toward miniaturization. Thanks to advancements in manufacturing processes such as surface-mount technology (SMT), PCBs have become smaller and more densely populated with components. This miniaturization has enabled the creation of smaller, lighter, and more portable electronic devices, from smartphones and tablets to wearables and IoT sensors.

Multilayer PCBs

The introduction of multilayer PCBs has been a game-changer in electronics design. These boards consist of multiple layers of conductive traces and insulating substrate, allowing for complex, high-density circuits. Multilayer PCBs improve signal integrity, reduce electromagnetic interference, and provide more design flexibility. As a result, they are widely used in high-performance and compact devices like high-end servers and advanced automotive electronics.

Improved Materials

Advancements in materials used in PCB manufacturing have greatly enhanced the durability and performance of PCBs. High-quality substrates, such as FR-4, polyimide, and ceramic materials, have become standard choices for various applications. These materials offer better thermal stability, lower signal loss, and increased resistance to environmental factors like moisture and chemicals.

3D PCB Design

Traditional PCBs were flat and limited to two dimensions. However, 3D PCB design tools and techniques have enabled designers to create complex, three-dimensional PCBs. This is particularly valuable in applications with significant space constraints, such as aerospace and automotive industries. 3D design helps optimize component placement, cooling, and signal routing.

Design Software

The evolution of PCB design software has simplified the design process and increased productivity. Modern tools offer auto-routing, design rule checking, and simulation capabilities. These software packages enable designers to quickly iterate and test different designs, reducing the time and cost of development. Additionally, collaborative capabilities have improved, allowing geographically dispersed teams to work seamlessly on the same project.

Improved Thermal Management

Efficient thermal management is crucial for maintaining the reliability of electronic components. Advanced PCB design includes features like heat sinks, vias, and thermal pads, which help dissipate heat effectively. New materials with enhanced thermal conductivity have also been developed to address the growing need for efficient cooling in high-performance devices.

Flex and Rigid-Flex PCBs

Flexible and rigid-flex PCBs have gained popularity due to their versatility and adaptability. These boards can be bent, folded, or twisted to fit into non-standard enclosures or applications, such as wearable devices and medical implants. Their ability to reduce the need for bulky connectors and cables makes them ideal for space-constrained designs.

Signal Integrity and High-Speed Design

As electronics have become faster and more powerful, signal integrity has become a critical concern. PCB designers now use specialized techniques and simulation tools to ensure high-speed signals propagate accurately, with minimal distortion or noise. Improved design practices, including controlled impedance and differential pair routing, have become standard for high-speed applications. The ongoing improvements in PCB design have revolutionized the electronics industry, making it possible to create more compact, powerful, and reliable devices. The miniaturization of components, adoption of multilayer PCBs, advanced materials, 3D design capabilities, and software tools have all played pivotal roles in this transformation. As technology continues to evolve, we can expect further innovations that will push the boundaries of PCB design, leading to even more advanced and efficient electronic devices in the years to come.

Leave a Reply