If you’re thinking of getting into laser engraving or you’re already doing it and want to level up, choosing the right machine makes a big difference. There’s a bunch of options out there, and the last thing you want is to buy something that doesn’t suit your needs, wastes time, or leaves you frustrated. That’s why it helps to look at quality laser engraving machines before you decide.

In South Africa, the demand for laser engraving is growing fast. People are using these machines for custom gifts, signage, industrial parts, awards, branding, jewellery, woodwork, leather goods — you name it. But all laser engravers aren’t the same. They differ in power, size, build quality, software compatibility, and what materials they can handle. Getting clear on what you need before you spend your money saves headaches later.

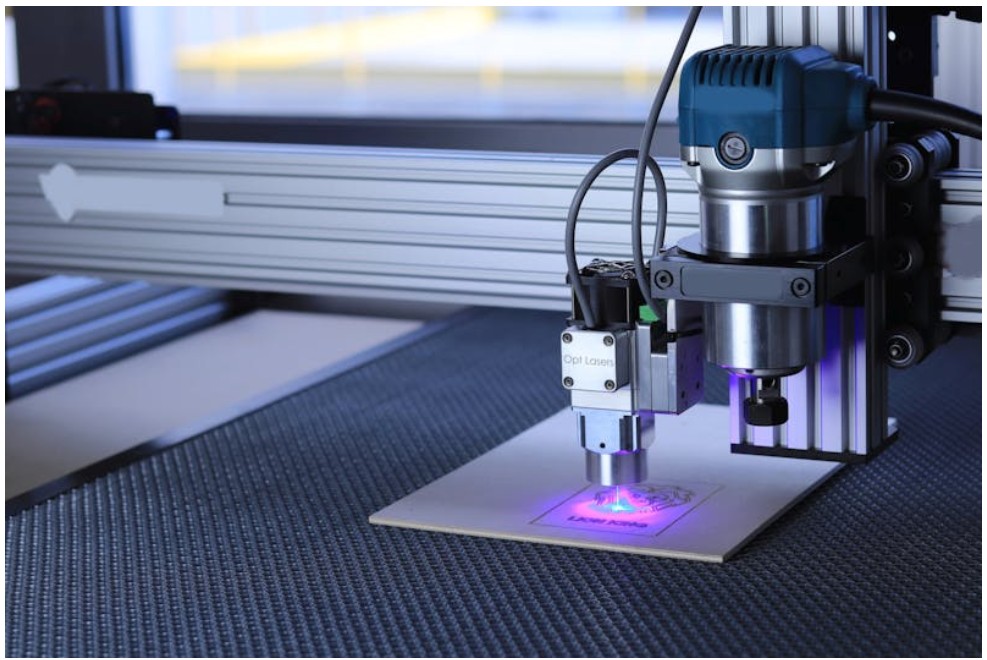

One of the biggest mistakes I see is jumping straight to the cheapest machine. It might look good on paper, but if it can’t run consistently, or it struggles with thicker materials, you’ll regret it. A solid machine will give sharper detail, run longer without breakdowns, and handle a wide range of materials like acrylic, wood, leather, MDF, glass, and even some metals. That versatility matters, especially if you want to grow your business or take on different kinds of work.

When you’re looking at options, think about what you’ll be doing most. Are you engraving small items like keyrings and name tags? Or are you planning on larger panels and signage? Do you need high power for deeper cuts, or precise detail for fine engraving? Answering these questions helps you choose the right wattage and bed size. Too small, and you’ll outgrow it fast. Too big, and you’re paying for stuff you don’t use.

South African businesses also have to think about support and parts. A machine is a long-term investment. You want one where you can get parts locally, reliable customer support, and people who know the gear if you need help. Buying from a reputable local supplier means shorter wait times for spares and advice — no long overseas delays, no guessing if a replacement part will fit.

Good laser engraving machines come with software that’s easier to use too. That might not sound like a big deal until you’ve spent hours trying to figure out a clunky interface. Better software means faster setup, fewer mistakes, and better results — especially if you’re juggling different file types or engraving detailed artwork.

Another thing worth thinking about is how intensively you’ll use the machine. Hobbyists and light users might be fine with entry-level gear. But if you’re running a workshop or production line, you want sturdier build quality, better cooling systems, and reliability. A machine that can run all day without overheating keeps production smooth and customers happy.

In the end, picking the right laser engraver comes down to knowing your needs and matching them with a machine built to meet them. Don’t rush it. Compare specs, think about future growth, and don’t just chase the lowest price. You want gear that’s reliable, easy to work with, and backed by support you can count on here in South Africa. If you’re ready to check out solid options and see what works for you, take a look at this range of laser engraving machines. Good machines make your job easier, your work better, and your business run smoother.

Leave a Reply